Launch Pad

Design

A lot of design and effort has gone into the Launch Pad. It is not intended to be quick and easy set up like a trailer or tripod design. The entire Launch Pad was designed and built with the intention of mounting cameras for photographing rockets.

Key Design Factors

- Very wide base for Stability

- Staked in for added strength

- Tower is hinged for loading

- Easily supports cameras

Detailed Description

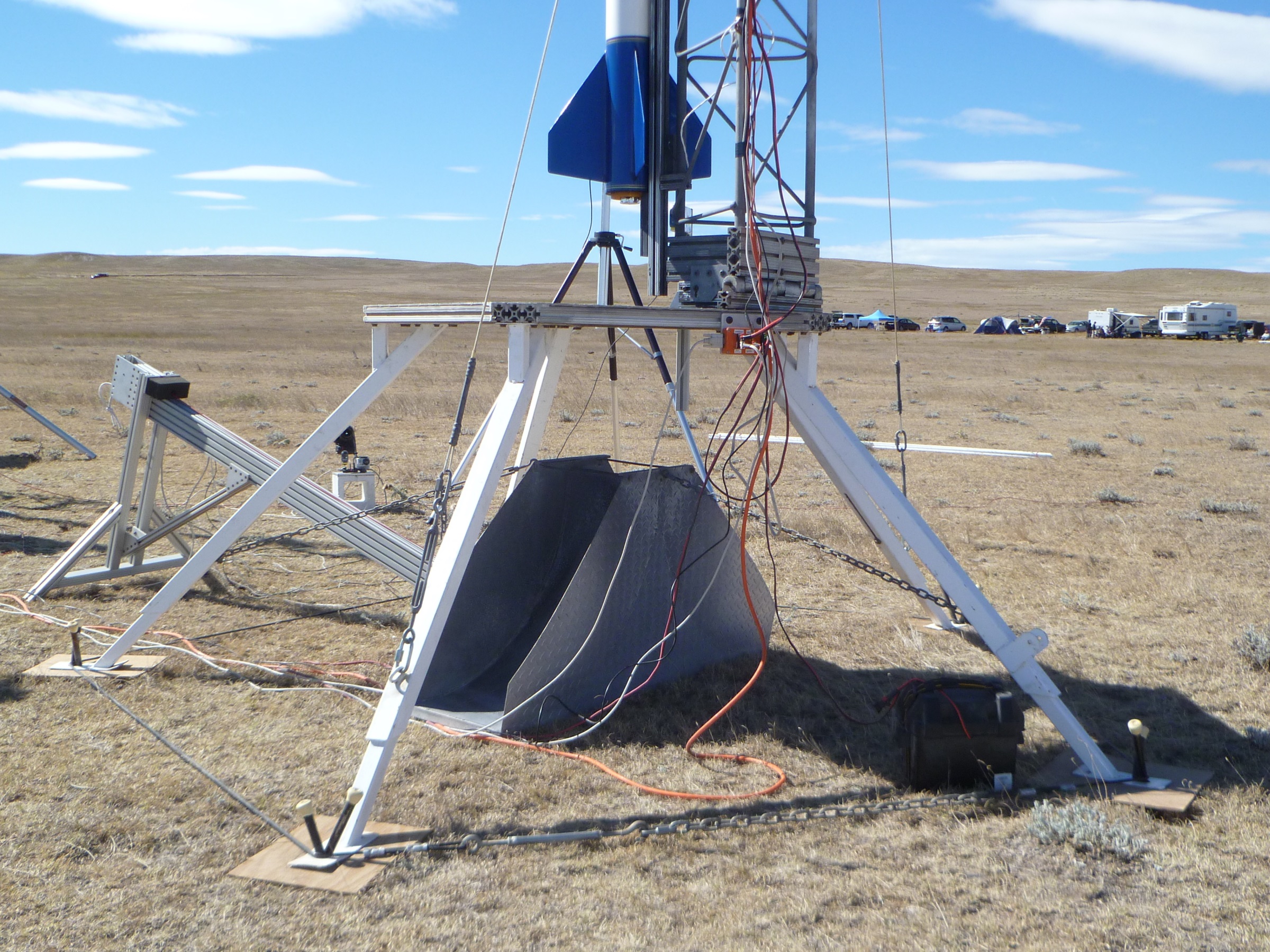

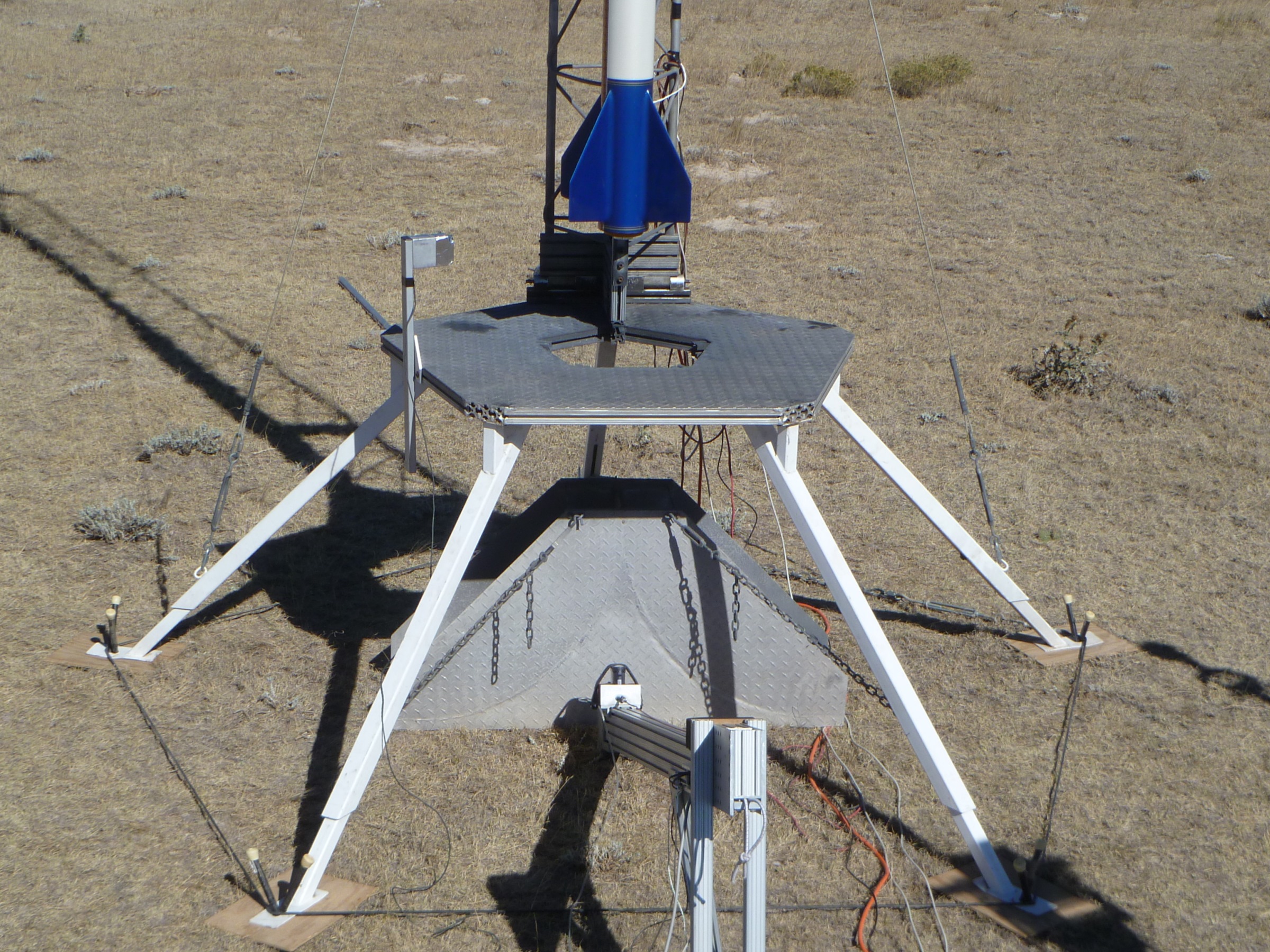

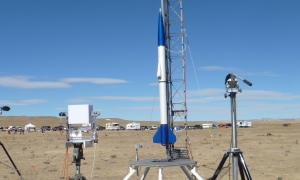

The Launch Pad itself is designed as a table with legs instead of a tripod or trailer design. It is a pentagon shape with five legs for additional stability. The base is constructed from 1515 size 8020 extruded aluminium welded to 1/8” diamond deck plate and each leg has an adjustable foot that can extend or retract for uneven ground. The legs were made from 2” square steel tubing and have been powder coated for a nicer finish. Also noticeable is that the legs are angled at 45 degrees from the base. This creates a huge 8 foot diameter platform for additional stability. In addition the angled legs allow for a greater blast area underneath the launch pad. The legs are bolted to the 8020 aluminium with 10 bolts. The legs are staked into the ground with two 5/8” steel stakes and to prevent any chance of spreading, there is a steel wire cable that surrounds the legs and is tightened with a turn buckle.

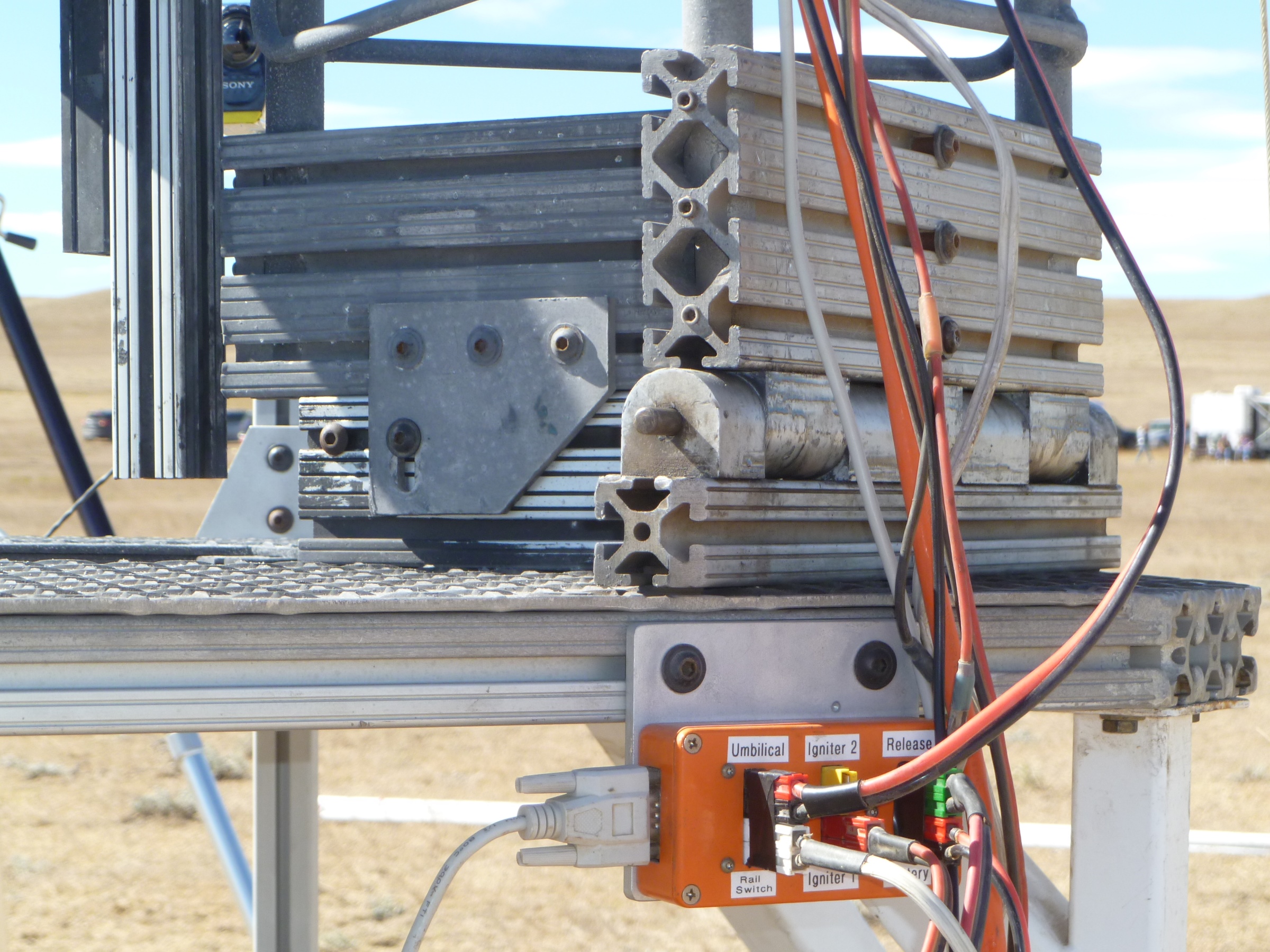

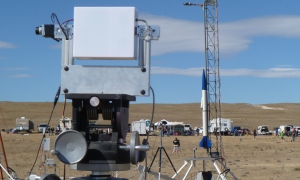

The launch tower itself is commercial antenna tower with the rail bolted to one leg of the tower. However, there is about a 3 inch stand off from the tower to the rail allowing for additional clearance when needed. The tower provides a great platform to mount some of the cameras as well as guide the rocket during lift off. At the top of the tower there is an arm that extends out about 4 feet to one side of the tower that cameras are mounted. The ends of the tower sections have 8020 aluminium attached. For the base this allows a hinge to attach the tower to the base. For disassembly the pin of the hinge is removed and the tower can be removed.

The tower can be bolted down to the base of the launch pad but also there are two guy wires that run from the tower to two of the back legs of the launch pad and can be tightened with turn buckles. The guy wires are designed so that the cables pulled slightly forward preventing the tower from falling backwards as well as preventing any side to side motion. In addition having the guy wires attach to the legs instead of in the ground, the length of the guy wires would always be the same.

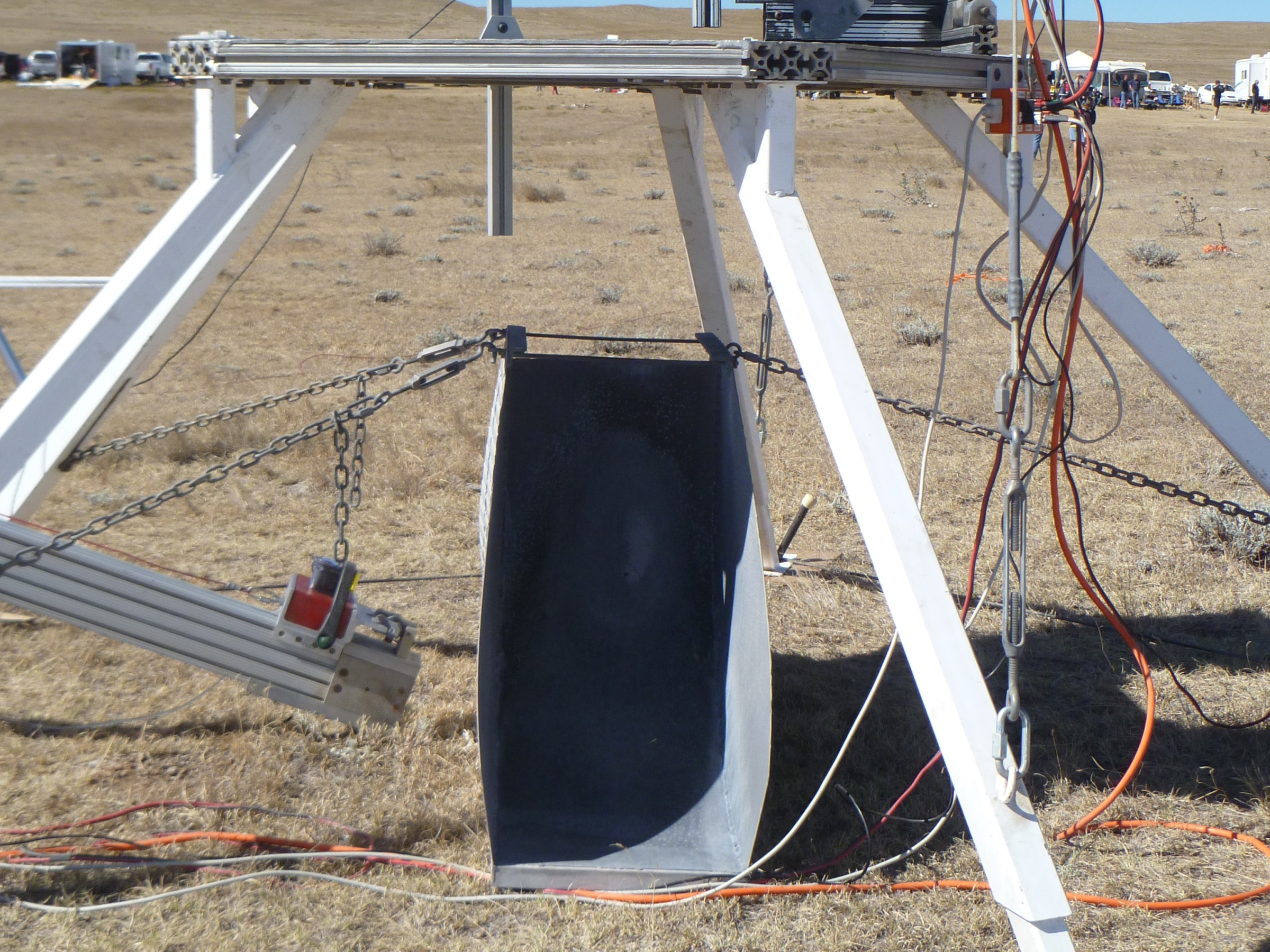

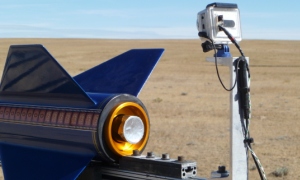

The pad base has a pentagon shaped hole in it to allow the blast of the motor to go underneath the launch pad. A solid plate can be installed in the hole if desired but mostly it is not used. Below the launch pad is a blast deflector that deflects the blast to the sides of the launch pad. This allows the slide mount to be located underneath the launch pad during motor ignition. The blast deflector is held in place with chains attached to the pad legs and tightened with turn buckles.